SELF-SANITIZATION AGAINST BACTERIA AND FUNGI

Transfer units

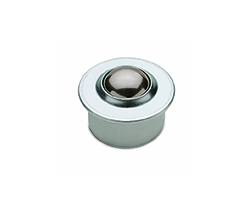

Elesa presents ball transfer units available in technopolymer, ESD conductive technopolymer, and steel. Ball transfer units are are ideal for applications on transfer and conveyor lines or the end of production lines. They facilitate both linear and rotary movements capable of handling heavy loads.

The self-lubricating technopolymer construction does not require lubrication with oils and greases and ensures maximum cleanliness. The stainless steel ball, supported by other smaller spheres, lends itself to handling loads with sharp and angular surfaces. In addition, since these are corrosion-resistant materials, it is possible to wash them frequently.

Alternatively, steel ball transfer units are made of a metal body within which a main sphere, supported by other smaller spheres, facilitates the handling in every direction of loads applied on flat surfaces (e.g. conveyor tracks).

The choice of which ball transfer unit to use must be made taking into account both the weight and the size of the load to be transported. The maximum distance between transfer units (on a flat surface) is obtained by dividing the smallest size of the load to be transported by 2.5. In this way you will be ensured that a load will always be supported by at least three ball units to prevent tipping due to empty spaces. As far as weight is concerned, since the load will certainly be supported on at least three points, each individual element will have to bear a load corresponding to the total weight divided by three.

The transfer units range also contains technoplymer roller transfer units.