SELF-SANITIZATION AGAINST BACTERIA AND FUNGI

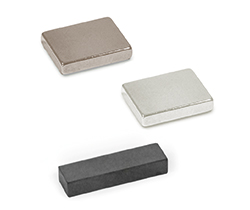

Unshielded magnets

ELESA unshielded magnets are ideal for a range of industrial and production applications. They are typically fixed in place using adhesive, and one surface concentrates all their magnetic energy. When used without an air gap, unshielded magnets have a lower adhesive force than shielded magnetic systems as shielding greatly increases the intensity of the attraction force.

Unshielded magnets are crafted using high quality steel and are available in rectangular, cylindrical, ring and bar shapes of various dimensions and thicknesses. They are durable and can withstand extreme high temperatures and corrosive environments. Unshielded magnets are made using an array of ferromagnetic materials (ferrite magnets, aluminum, nickel, cobalt magnets, samarium cobalt magnets, and neodymium iron boron) for specific values of attraction strength, resistance to temperatures and corrosion, and workability.

Unshielded magnets do have more of a possibility of demagnetization over time, and because they are not shielded, the magnetic field dispersion can extend beyond the magnet and potentially impact nearby components. They also have the ability to interfere with more sensitive electronic devices. Investigate our Technical Data page for more detailed information about ELESA’s range of industrial magnets.

Whatever components you need for your facility operations, ELESA has the parts to meet your requirements. Get in touch with our sales team to learn more about our available unshielded industrial magnet options or to inquire about a specific size or material and common customization options. Request a catalogue to see all of our quality components at a glance, where you can also shop Ganter branded products. Streamline and maximize your production goals with genuine, high-quality, ELESA parts.