SELF-SANITISATION AGAINST BACTERIA AND FUNGI

Technopolymer

Material

Glass-fibre reinforced polyamide based (PA) technopolymer, RAL 9005 (C9) black colour or grey RAL 7042 colour, matte finish.

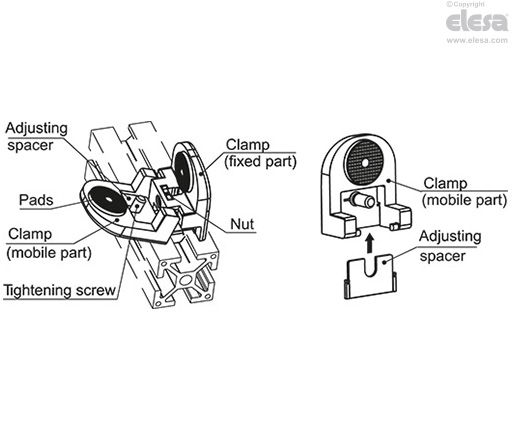

Pads

Thermoplastic elastomer, hardness 80, Shore A, overmoulded.

Adjusting spacers (included in the supply)

Polyamide based (PA) technopolymer, RAL 7042 grey colour, for fastening the clamp to panels of variable thickness (see table).

Standard executions

- PC: steel screw and nut.

- PC-SST: stainless steel screw and nut.

| s panel thickness [mm] | Adjusting spacer to be used PC.35-4-8 |

| 3.1 < s < 4.1 | - |

| 4.1 < s < 5.1 | 5 mm |

| 5.1 < s < 6.1 | 6 mm |

| 6.1 < s < 7.1 | 7 mm |

| 7.1 < s < 8.1 | 8 mm |

| s panel thickness [mm] | Adjusting spacer to be used PC.35-6-12 |

| 6.1 < s < 7.1 | - |

| 7.1 < s < 8.1 | 8 mm |

| 9.1 < s <10.1 | 10 mm |

| 11.1 < s <12.1 | 12 mm |

Features and applications

- The product is in compliance with the Machine Directive (2006/42/CE) that provides for the retention of all the clamping elements even in the open position (ELESA patent). The two parts of the clamp are connected by means of an articulated joint and they have got a seat for housing a steel or stainless steel screw and M5 nut.

- The special dimensions of the clamp allow its assembly on profiles with a width of 25 mm or higher.

- The panel assembly into the clamp does not require any drilling which may cause cracks in the panel.

- The chemical bond of the overmoulded pads makes them a single body with the clamp. The embossed surface avoid any possible sticking of the pad to the panel over the time.

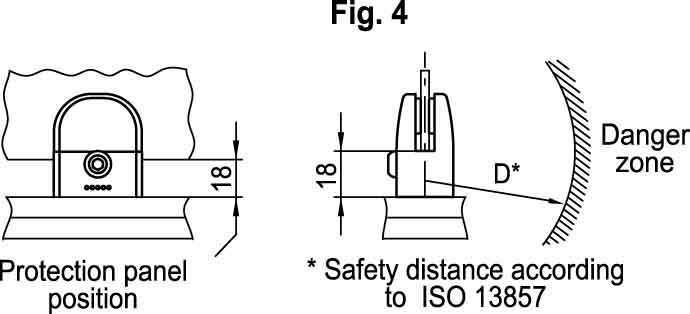

- To prevent machine danger zones being reached through any opening in the machine protection structure made of panels fixed with the PC clamp, it is necessary to keep a safety distance (Fig. 4) according to ISO 13857, section 4.2.4 (the safety distance is the minimum distance required between a protection structure and a potentially dangerous component of the machine).

Technical data

If the clamp is opened, the tightening screw does not yield below an extraction force of 250 N, without coming out from its housing.

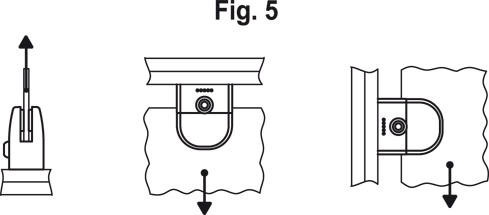

During the tests carried out in our laboratories under controlled temperature and humidity (23°C-50% R.H.), under given conditions of use and for a limited period of time, the maximum load of each clamp is of 100 N (fig. 5).

The tightening screw of the panel and the assembly screws of the clamp on the profile have got the same hexagonal seat. Thus, it is possible to make the assembly by using only one hexagonal key (Key 4).

Maximum tightening torque for the screw = 3.5 Nm.

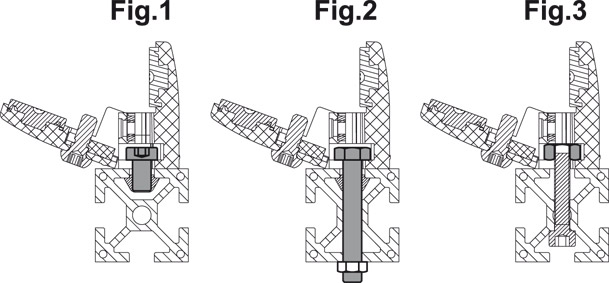

Assembly of the clamp on the profile

- M6 shorted cylindrical head screw with DIN 7984 hexagon socket (fig.1).

- DIN 933 M6 hexagonal head screw (fig. 2).

- DIN 439B or DIN 934 M6 hexagonal nut (fig. 3).