SELF-SANITISATION AGAINST BACTERIA AND FUNGI

Hygienic Design

DESIGN, MATERIALS AND SURFACE TREATMENTS AT THE SERVICE OF HYGIENE

Operating elements in food processing and pharmaceutical plants: the Importance of Hygienic Design in Ensuring Cleanliness

Hygienic Design line offers a range of standard operating elements that help achieve optimal levels of hygiene.

Benefits & Advantages of Hygienic Design Components

The range includes standard components such as handles, clamping knobs and levers, as well as levelling feet, nuts, and screws, lever latches, indexing plungers, and spacer sleeves, designed in compliance with high standards in sanitary matters such as 3-A, EHEDG, and DGUV guidelines.

Read more

In food, paints and dyes, pharmaceutical and medical industries, maintaining maximum hygiene and cleanability of equipment and environments is becoming increasingly mandatory.

Minimising the risk of contamination of production allows for greater safety in preparations and more efficient processes to the benefit of human health. Today this is even more true due to the increased demand for products without added preservatives, or in minimal quantities, while still guaranteeing a longer shelf life.

Traditionally, the focus of hygiene control might have been on the immediate product zones. However, the reality is that airborne contaminants can spread to significant distances, and even seemingly insignificant corners can become breeding grounds for microorganisms, jeopardising the entire production line.

Designers know that building production facilities in these sectors requires that all components and surfaces meet specific production and quality standards.

Having a line of specific standard components, always available, not subject to minimum purchase quantities and with guaranteed performance, in some cases even certified, represents a strong competitive advantage.

This is where the unique Hygienic Design components come into play.

LEGAL BASIS

EN 1672-2:2009 “FOOD MACHINERY” Machines must be able to be cleaned, i.e. they must be designed and constructed so that dirt can be removed with the recommended cleaning methods.

MACHINERY DIRECTIVE 2006/42/EC Machines must be designed so that materials can be easily and fully cleaned before each use and no risk of infections or illness is created.

DIN EN ISO 14519:2008-07 Hygiene requirements for the design of machines.

DIN EN 1672:2009-07 Food machinery – General design principles – Part 2.

Hygienic Design Requirements

Specific design features are key factors in the production of Hygienic Design components in addition to the selection of quality raw materials.

Selection of raw materials

The choice of raw materials is crucial in the design of Hygienic Design components. Stainless steel is the material of choice for this type of component due to its resistance to corrosion, durability and ease of cleaning.

There are different types of AISI stainless steel offered in the range, from AISI 316L to 304 (including CF8).

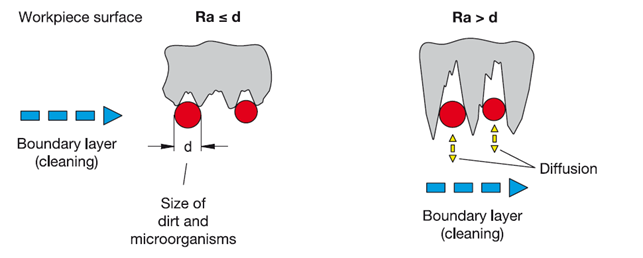

Surface finish and geometries

The surface finish of the components has a significant importance in preventing bacterial growth. In fact, a smooth and polished surface is less likely to host bacteria than a rough and unfinished one. By preventing the accumulation of liquids containing unwanted substances, self-draining surfaces further reduce the risk of contamination.

The roughness of the surface is measured in micrometers (µm) and a lower value indicates a smoother surface. Typically, a surface roughness of 0.8 µm or less is recommended for hygienic applications.

Geometries with large radii (6 mm or more) for rounded edges eliminate any cavities and recesses where bacteria can accumulate; seamless welds ensure there are no gaps or cracks, helping to further reduce debris deposition and making cleaning easier.

Seals

Particularly important are the H-NBR or EPDM synthetic rubber seals, which are FDA compliant. These seals allow the internal part of the mechanism to be sealed from the external environment, preventing the access of substances. The absence of cavities and recesses and geometries with large corner radii prevent the adhesion of impurities and facilitate cleaning operations.